The LGK series orifice plate flowmeter is a high range differential pressure flow device composed of a standard orifice plate and a multi parameter differential pressure transmitter (or differential pressure transmitter, temperature transmitter, and pressure transmitter).

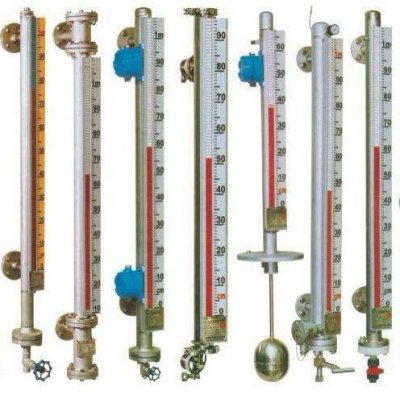

When the liquid level in the tested container rises and falls, the float in the main tube of the magnetic flap level gauge also rises and falls. The long-term magnetic steel inside the float is transmitted to the on-site indicator through magnetic coupling, driving the red and white flipping columns to flip 180 °.

Magnetic flip column level gauge is another type of side mounted, top mounted (bottom mounted) product developed for centralized control. It has the advantages of clear on-site indication and remote control.

UFZ float level gauges are available in both simple and windproof types. By utilizing the principle of buoyancy and force balance, a large float that matches the specific gravity of the measured medium is placed in the container to float on the liquid level of the medium.

The glass plate level gauge can be used to directly indicate the liquid level height in sealed containers, with advantages such as simple structure, intuitive reliability, and durability. However, the medium in the container must be non corrosive to steel, steel paper, and graphite pressure rings.

The UQZ floating ball reed level gauge switch consists of three parts: a magnetic levitation ball, a sensor, and a switch. When the magnetic levitation ball floats up and down along the guide tube as the liquid level changes, the magnetic steel inside the levitation ball attracts the reed tube at the corresponding position in the sensor, causing a change in the total resistance (or voltage) of the sensor.

Small glass tube level gauge, also known as transparent small tube level gauge, has no scale display. Transparent glass tubes can be used to check the liquid level and can be installed with single and double threaded ends.

The UGS color quartz tube level gauge (hereinafter referred to as the color level gauge) is developed using domestic and foreign technology. It utilizes the principle of natural light refraction and reflection in liquids, and with the help of red and green sheets, the liquid phase is displayed in green and the gas phase is displayed in red during measurement.

Ultrasonic level gauge is a digital level instrument that processes signals with a high-performance microprocessor. In measurement, ultrasonic pulses are emitted by sensors (transducers), and sound waves are reflected off the surface of an object and received by the same sensor.

Capacitive level gauges are suitable for continuous detection of various liquids under harsh conditions such as high temperature and pressure, strong corrosion, easy crystallization, and blockage.

Single or dual screen LED display. The range display can be adjusted arbitrarily according to the working conditions. The linear input signal display range can be set arbitrarily, and can also be displayed as a square root, with a small signal cut off.

Input various flow sensor signals (such as vortex street, turbine, electromagnetic, Roots, elliptical gear, dual rotor, orifice plate, V-cone, Annubar, mass flow, and other flow meters);

1. Eight contact type (please specify when ordering level type) input signal, corresponding to eight flashing display signal lights. 2. The input signal can be either normally open or normally closed (if not specified during ordering, it will be shipped as normally open, but can be set through a jumper).

1、 Functional characteristics of intelligent flow totalizer Full range automatic temperature and pressure compensation calculation, with any compensation method set Linear integration and square root integration can be set arbitrarily

1. Various analog inputs or frequency inputs. 2. Triple display of process quantity, given value, and control quantity. 3. PID regulator positive and negative action selection. Manual automatic bidirectional undisturbed switching.

Product Center Product center

Mobile: 13909602360; 15056558682

Address: No.10 Jingjiu Road, Tianchang Economic Development Zone, Anhui Province